Burning Toilet

Burning Toilet

The paper bag containing "excrement" is released into the combustion chamber after using the toilet. High temperatures and the air cause the excrement to evaporate. Residual heat and smoke is discharged through the exhaust pipe. Catalytic converters prevent unpleasant odors.

Key Features

- Urine and Feces Disposal: Use parchment paper or other materials to collect urine and feces, avoiding direct contact with the combustion chamber

- High-Temperature Treatment: Urine and feces are sent into the incineration chamber for high-temperature treatment together

- Effective Incineration: The temperature in the combustion chamber can reach 400°C to 600°C, effectively incinerating feces

- Simple Operation: The flushing toilet is designed with an easy-to-use operation interface

- Odor Control: No unpleasant odors during incineration

- Ash Collection: The combustion chamber is designed with ash collection system for easy subsequent treatment and utilization

Applications

- Ideal for areas without water access

- Remote locations where traditional plumbing is not available

- Camping, RVs, boats, and other mobile applications

- Emergency sanitation solutions

- Eco-friendly alternative to chemical toilets

Technical Parameters

| Parameter | Electric | Diesel | LPG |

|---|---|---|---|

| Fuel type | Electric | Diesel | LPG |

| Rated voltage | DC12V | DC12V | DC12V |

| Thermal power (KW) | 2 | 3 | 3 |

| Fuel consumption | 2KWh | 300ml/h | 240g/h |

| Gas pressure | / | / | 30mbar |

| Electric supply | AC 250V | / | / |

| Max power (W) | / | 120 | 70 |

| Rated power (W) | 105 | 5 | 15 |

| Working temperature | -40°C ~ +50°C | -40°C ~ +50°C | -40°C ~ +50°C |

| Working altitude | ≤5000m | ≤5000m | ≤5000m |

| Dimensions (mm) | 510×440×560 | 510×440×560 | 510×440×560 |

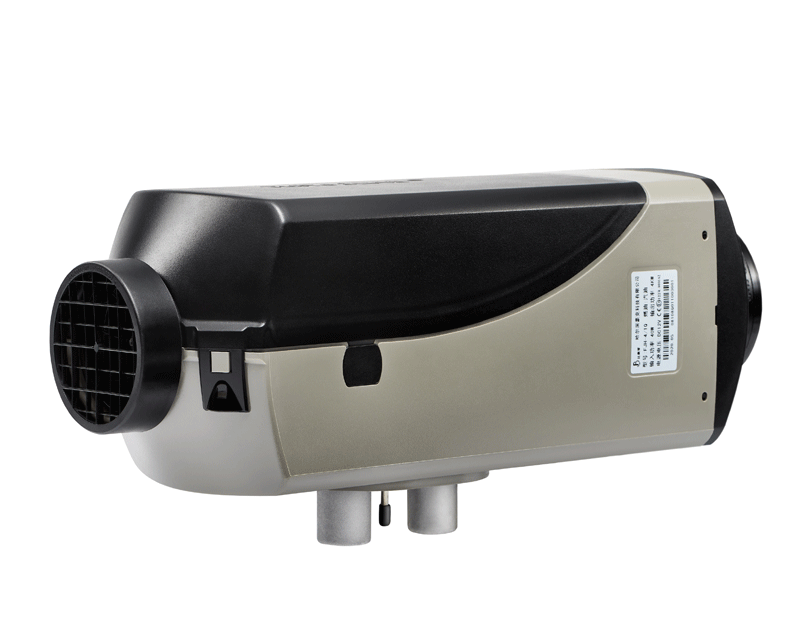

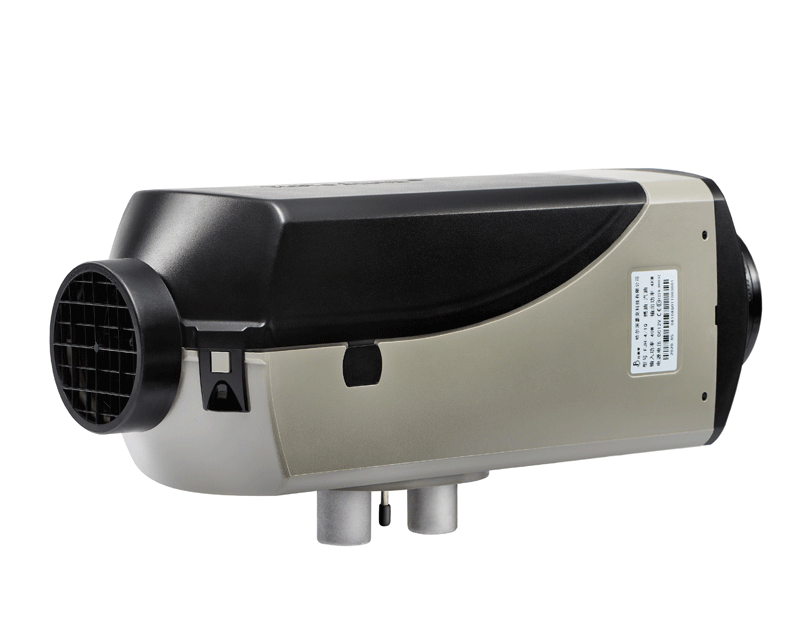

Product Image

Product Advantages

Energy Saving

High-efficiency heating and solid-liquid separation technology improves thermal energy utilization efficiency and reduces energy consumption.

Environmental Protection

No wastewater is generated during incineration, reducing pollution to the environment.

Water Saving

A flushing toilet does not require water for flushing, saving a large amount of water resources.

No Blockage

Without water flow flushing, the incineration toilet will not have the problem of blockage.

Simple Maintenance

An incineration toilet does not require complex pipe systems and pretreatment facilities, and maintenance costs are lower.

No Odor

Through special design, the odor generated during incineration is controlled within the toilet and will not leak out.

Applications

- Ideal for areas without water access

- Remote locations where traditional plumbing is not available

- Camping and RV applications

- Boats and marine vessels

- Emergency sanitation solutions

- Eco-friendly alternative to chemical toilets