Sanitário Incinerador

Sanitário Incinerador

O saco de papel contendo "excrementos" é libertado na câmara de combustão após usar o sanitário. Altas temperaturas e o ar causam a evaporação dos excrementos. O calor residual e a fumaça são descarregados através do tubo de escape. Conversores catalíticos previnem odores desagradáveis.

Key Features

- Descarte de Urina e Fezes: Use papel vegetal ou outros materiais para coletar urina e fezes, evitando contato direto com a câmara de combustão

- Tratamento de Alta Temperatura: Urina e fezes são enviadas para a câmara de incineração para tratamento de alta temperatura juntas

- Incineração Eficaz: A temperatura na câmara de combustão pode atingir 400°C a 600°C, incinerando eficazmente as fezes

- Operação Simples: O sanitário de descarga é projetado com uma interface de operação fácil de usar

- Controle de Odor: Sem odores desagradáveis durante a incineração

- Coleta de Cinzas: A câmara de combustão é projetada com sistema de coleta de cinzas para fácil tratamento e utilização posteriores

Applications

- Ideal para áreas sem acesso à água

- Locais remotos onde o encanamento tradicional não está disponível

- Camping, RVs, barcos e outras aplicações móveis

- Soluções de saneamento de emergência

- Alternativa ecológica aos sanitários químicos

Technical Parameters

| Parameter | Electric | Diesel | LPG |

|---|---|---|---|

| Tipo de combustível | Elétrico | Diesel | GLP |

| Tensão nominal | DC12V | DC12V | DC12V |

| Potência térmica (KW) | 2 | 3 | 3 |

| Consumo de combustível | 2KWh | 300ml/h | 240g/h |

| Pressão do gás | / | / | 30mbar |

| Alimentação elétrica | AC 250V | / | / |

| Potência máx (W) | / | 120 | 70 |

| Potência nominal (W) | 105 | 5 | 15 |

| Temperatura de trabalho | -40°C ~ +50°C | -40°C ~ +50°C | -40°C ~ +50°C |

| Altitude de trabalho | ≤5000m | ≤5000m | ≤5000m |

| Dimensões (mm) | 510×440×560 | 510×440×560 | 510×440×560 |

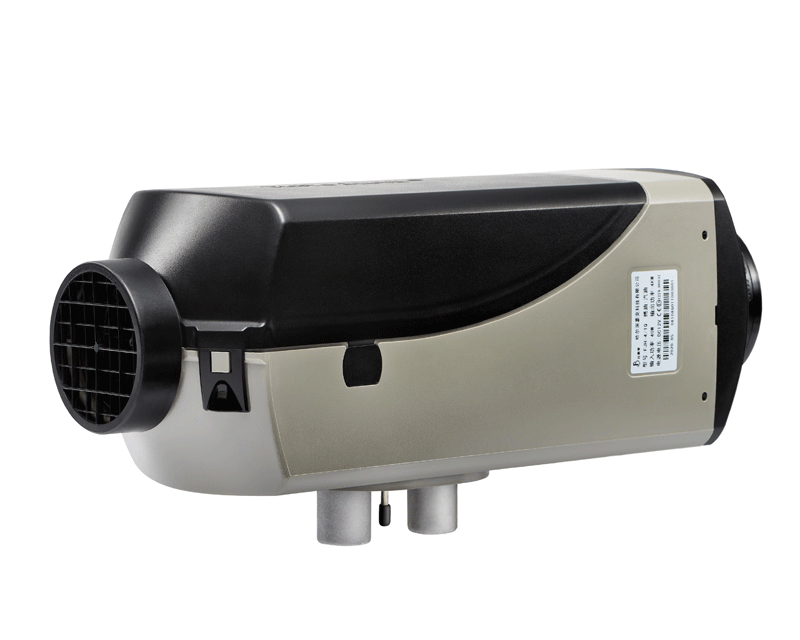

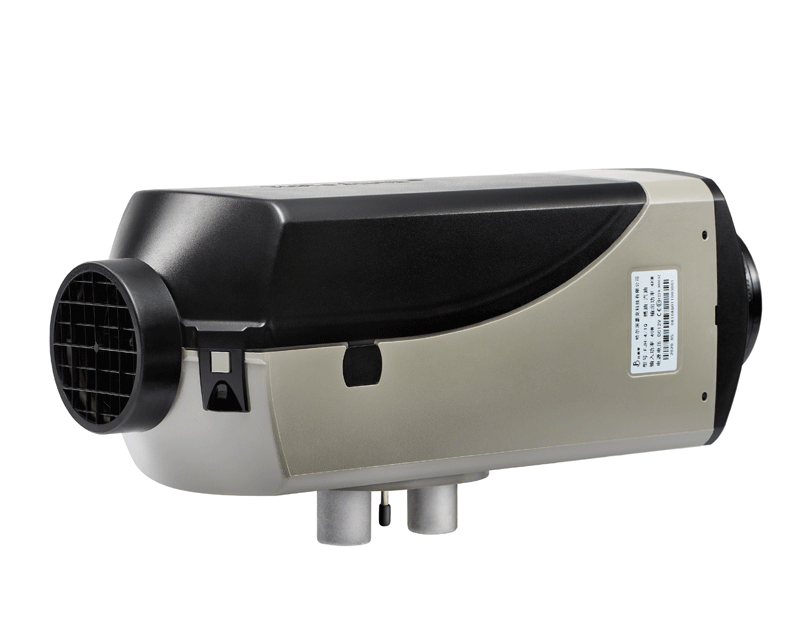

Product Image

Product Advantages

Energy Saving

High-efficiency heating and solid-liquid separation technology improves thermal energy utilization efficiency and reduces energy consumption.

Environmental Protection

No wastewater is generated during incineration, reducing pollution to the environment.

Water Saving

A flushing toilet does not require water for flushing, saving a large amount of water resources.

No Blockage

Without water flow flushing, the incineration toilet will not have the problem of blockage.

Simple Maintenance

An incineration toilet does not require complex pipe systems and pretreatment facilities, and maintenance costs are lower.

No Odor

Through special design, the odor generated during incineration is controlled within the toilet and will not leak out.

Applications

- Ideal for areas without water access

- Remote locations where traditional plumbing is not available

- Camping and RV applications

- Boats and marine vessels

- Emergency sanitation solutions

- Eco-friendly alternative to chemical toilets